The latest and quite possibly the greatest AWISA show set new visitor records in an environment that isn’t the norm for major trade shows with heavy machinery, but worked very well. In fact, the show received a thumbs-up from the more than ten thousand visitors to Australian furnishing’s blue ribbon event.

AWISA was held at the new Sydney International Convention Centre (ICC); a facility spanning multiple levels. The AWISA organisers put a lot of effort into making the venue work and very soon, any concerns about upstairs-downstairs were quickly dispelled. The reality was that for the design exhibitors upstairs, you could actually hear yourself speak and for the machinery exhibitors downstairs, the various stands seemed more accessible. One or two exhibitors may re-think their stand location for the next show but every exhibitor Supplier spoke to praised the event and the facility and will be back again in two years. Australia needs a National show and AWISA; while attracting fewer visitors than the more densely populated countries, punches above its weight in terms of quality; value for money; visitors per capita and relevance to the local industry.

This year the value of AWISA to suppliers of machines, tools, equipment and hardware was evident in the high number of overseas supplier principals that attended the show. Product experts were everywhere to explain and demonstrate the many new pieces of equipment, software and hardware at the show. The upstairs design hall was no exception where the very latest design elements from around the World were on show. It was an exceptional experience and every visitor took some new ideas from the event. The suppliers were very pleased as well, with most reporting excellent sales from the show and many reporting sales records broken, an indication of the strength of Australia’s wood manufacturing sector.

The highlights from AWISA were everywhere. CAD design and manufacturing software continues to impress with World-leading software available to the Australian manufacturer. It’s getting easier to use; more powerful; more visually appealing from a design viewpoint and generally supports the latest industry 4.0 efforts for more total control of your equipment and manufacturing processes. This year, software platforms emerged to control even more of your manufacturing processes. All the major suppliers can provide a suitable software platform not only to control the machinery; but to report on its efficiency; allow remote access and control; troubleshoot any problems that may arise and predict maintenance issues. The major players can all provide overarching software for their computer based equipment. For example, Biesse has Sophia, released at the last Ligna show and SCM has Maestro Connect, released more recently at the Xylexpo fair in Italy. There is more to follow with Homag ‘turning-on’ their Tapio platform in the US recently and planning to release it in Australia in the very near future.

On the machinery front there were many highlights. One that caught our attention was the Anderson GS Series of machines from Wood Tech with a magnetic drive similar to what is used for the high-speed maglev trains. A series of magnets push and others pull the work-head up and down the axes at speeds unheard of before this machine. No wear and tear, less noise, incredible acceleration of the axes resulting in an almost 50% reduction in machining times. Also from Wood Tech we saw the Australian-made ‘Hive’ robotic vertical panel management system that in its 360-degree version will store 2,400 components on only 100 square metres of floor space.

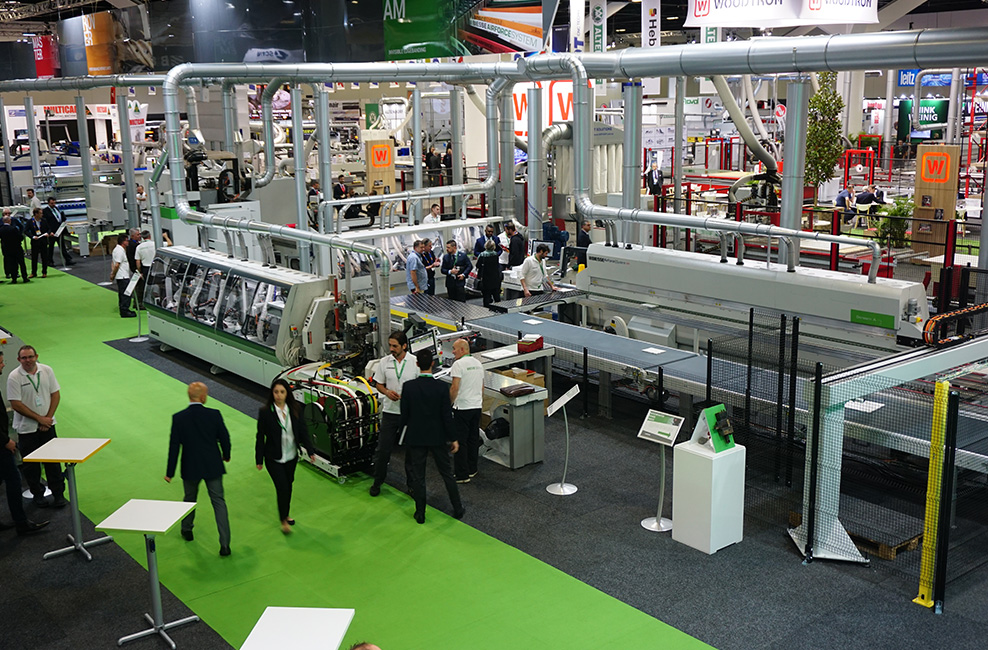

From Homag we saw the continuing development of operator assisted working with their intelliguide operator assist system. Available in three levels, there is no longer any worry about machining the wrong part; intelliguide makes sure of the right part every time and if the wrong part is inserted, the software will alter the program so the right processing is done to that part. The Homag Group also presented part of an automated cell previously displayed at the Xylexpo in Milan where it won a special award. On top of a beam saw sits a robot that is integrated into the saw machining cycle. No operator involvement is required to cut the parts of sort them onto several pallets. In the fuller version the robot takes the panels from the saw and feeds them onto either an edge banding or a CNC line with either standard or vertical CNC processing centres. It’s beautiful to watch and all the major players can supply a solution to meet every need.

Woodtron continues to improve its vertical panel storage system that doesn’t rely on floor space and mixed stacks of panels. Not at AWISA but soon to come to Australia; SCM has a new combined end cutting and rounding unit for edge-banding machines that combines end cutting and rounding operations, executed with one tool, allowing the design of machines with a small footprint. It won first place at the Xylexpo awards a few months ago and is great news for someone who needs a fully-functional edge bander in a small package. Stefan Kremer from Felder was there on Felder’s biggest stand to date with the boys from FSA (Window Solutions) demonstrating a European-style window processed on standard spindle moulders. Altendorf were showing off their new group and there’s likely to be more news later this year. An Altendorf panel saw with a cut-away table was on display to highlight the robust construction of this much-loved classic.

In the design hall we saw many leading products from the many international suppliers. Notable amongst these were the Blum Aventos HK Top; a very neat push-to-open stay-lift for overhead cabinets. The Grass Tiomos concealed hinge is completely hidden inside the side and door panels and is an extremely neat fitting. Hafele showed the Canto corner lift and competitor Hettich, their wingline folding door system. Vauth Sagel had a self-closing lazy susan product for corner cabinets called VS Cor Spin (formerly Galaxy Spin) but one item that really stood out was the Concelo waste bin from Hideaway bins. Cleverly designed and much more than just a bin, this product shows what some effort, good design and clever thinking can do to a product that is equally as important to a kitchen as the refrigerator or dishwasher.

AWISA is much more than a local show; it’s an international event and brings the very best the World has to offer to the local trade. It’s almost certain the next event in 2020 will again be held in Sydney and you can expect that one to be even better than this. Ligna in Hannover; Interzum in Cologne; AWFS Las Vegas (all three in odd-numbered years) and Holz-Handwerk in Nuremberg this year are the international shows most likely to be visited by Australian manufacturers but AWISA is the one not to be missed and a record ten thousand visitors gave it the thumbs-up.