AWISA is over and millions of dollars have been spent by Australia’s manufacturers on new machinery. If you are yet to make that all-important purchase, here are a few points to consider from leading industry experts.

Investing in a CNC machine is a little like buying a Ferrari. There is expectation of high performance and it will cost almost as much. Getting the right machine will contribute to the growth of a company: the wrong machine could end in disaster. Australia is one country where high technology is receiving particular interest.

Supplier’s technology editor Phil Ashley asked a number of people around the world two questions about CNC equipment. Responses were sought from the export department of Homag Germany; British Columbia Institute of Technology, Canada; Centre for Advanced Wood Processing, University of British Columbia, Vancouver, Canada and FIRA (Furniture Industry Research Association), England. Their responses are relevant to the issue of purchasing CNC machines.

The first question was: “What are the most important issues a manufacturer using CNC machinery needs to get right?”

The responses were: quality of the finished products; being able to make various parts with all different kind of shapes; very flexible, easy to program; return on investment; very fast; all kinds of different material can be processed; competitive in price and quality; technical support; training and after sales service; online support. They also said: “what they think the machine will do and what the machine will actually do and machine specification to activate what is necessary.”

Buying the right machine for the job; understanding the capabilities and ensuring that the machine can be run enough to justify the investment were also high on the response list.

The second question was: “What are the opportunities that a manufacturer using CNC equipment has?”

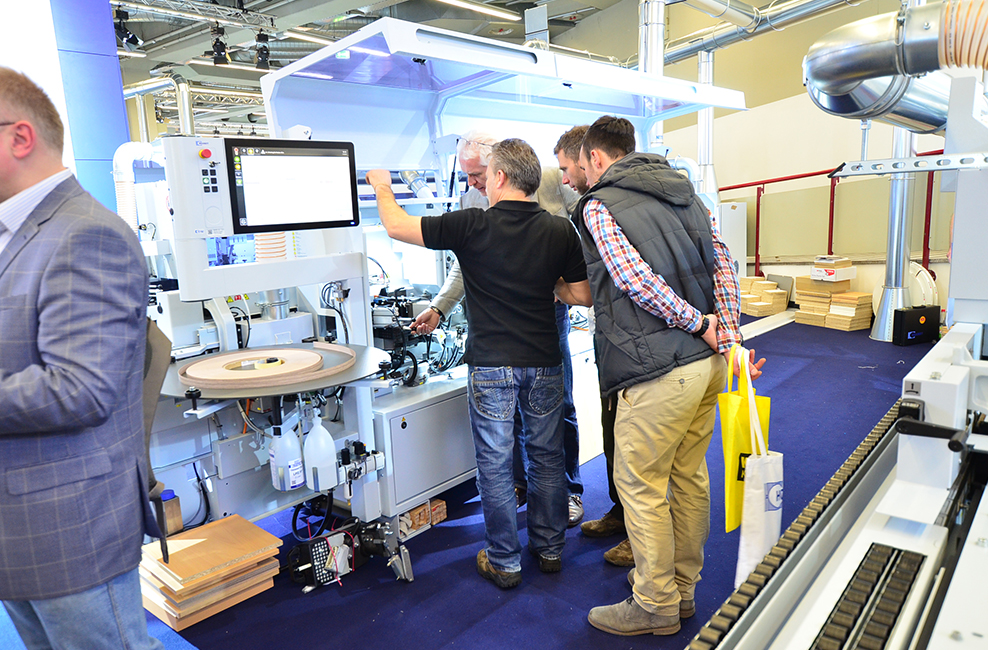

The responses were: to be number one in their market; fast delivery time of the products; one step ahead of the competitors; precision, versatility, and speed; quick response (for one-offs); flexible manufacturing and speed; accuracy of work; machine management reports; CAD-CAM (fly by wire); easy touch screen technology and more consistent quality and less reliance on skilled cabinetmakers, who are becoming scarce.