CABINET VISION Version 12 provides benefits for machining and greater control of parts.

The latest version of CABINET VISION delivers greater control and flexibility for the machining of part connections, empowering users to better automate and manage every aspect of production.

Released recently by Planit Cutting Edge Solutions in Australia, CABINET VISION Version 12 features an all-new connection manager that delivers complete control over the machining that occurs where two parts come together. This enables users to easily define and automate those connections.

As part of the recent release, Planit hosted their Planit Live Seminars across the country to give customers an insight into the new version. These seminars allowed customers to come and get a hands-on approach to the new version, to understand the benefits and discover how the new version will help their internal systems.

Blake Cugley, National Marketing Coordinator for Planit, commented that “Planit Live 2019 is the second time we have hosted this type of national seminar series for our customers. It was great to give our customers an update on not only CABINET VISION Version 12, but the latest updates from Vortek Spaces and to also announce the launch of AC Australia CAD CAM Solutions, our new division which will be focussing on ALPHACAM. We had a great response from our customers, many travelling a long distance to make one of our 6 seminars across the country. This was on the back of our first Livestream Webinar that we hosted for our Customer Care Members. Creating our own little TV Studio, our livestream gave clients the opportunity to get an early overview of Version 12. We even had a customer share a photo of himself streaming our Livestream on his boardroom TV.“

“When developing CABINET VISION Version 12, we were focused on giving our users more control over how their cabinets are constructed,” said CABINET VISION Global Product Manager Chip Martin. “The new connection machining in version 12 is a game-changer for automating how our customers connect their parts together, whether for cabinets or closets.”

This latest version also features a completely redesigned CABINET VISION Assembly Manager, which is utilised to specify construction methods and standardise the production of their products. In version 12, the assembly manager offers increased flexibility, including the ability to select connections per part, and an enhanced, user-friendly interface.

The new connection manager, along with the ability to assign connections in the CABINET VISION assembly manager, delivers unparalleled flexibility for defining and automating construction methods. This development offers greater control over every aspect of connection machining while maintaining both ease of use and part quality.

CABINET VISION Version 12 offers a direct link to the Leica Geosystems 3D DISTO™ measurement tool, which accurately captures 3D coordinates with the precision needed for project planning. Designed to eliminate unwelcome surprises due to measurement inaccuracies, this direct link with CABINET VISION enables users to drive the layout of jobs directly from the job site.

Planit Live also allowed Planit to collaborate with the team from CR Kennedy, who showcased their range of Leica Laser Measurers, including the recently released BLK 360. “Laser Measuring is becoming more & more essential to our industry as we continue to rely on accuracy within our manufacturing systems,” said Cugley, “and so collecting accurate data points with laser measuring is only going to take it to that next step”.

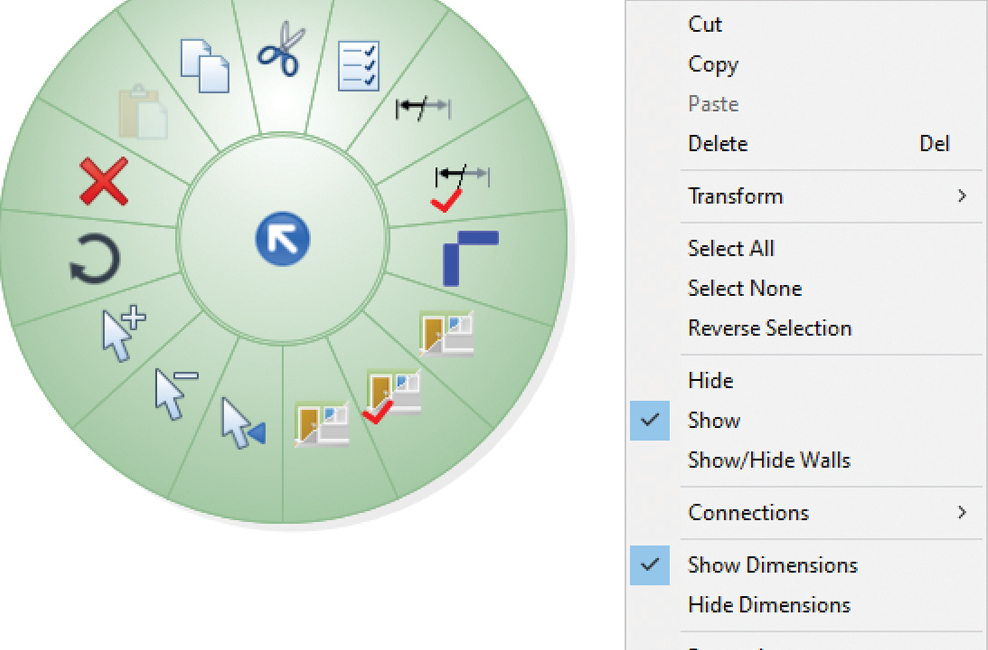

Among this latest version’s interface enhancements is the option to display all contextual, or right-click, menus as radial menus. Radial menus offer a number of key advantages — most notably speed and ease of use.

As Version 12 continues to be rolled out, Garry Thoroughgood, National Services Manager for Planit, also shared that the Planit Services Team have been holding ‘Local Install Days’ across the country & online, to give their customers assistance when installing Version 12, and conduct a system check one-on-one with a technician.

“It’s all about ensuring our customers have a good experience, and it’s also another way Planit wants to give back to the industry”.