The Open House event of SCM Group, a leader in the field of secondary woodworking technologies was held in Rimini from 31st January to 2nd February. The spotlight was on highly flexible modular automation systems and man-robot interaction. It’s a technology the Australian furniture industry is hearing about every day.

Automation through integrated robotics was the focus of the “Smart&Human Factory” event held at the Technology Centre of SCM Group Headquarters, in Rimini. One of the leading producers of secondary woodworking machinery; SCM Group hosted an exclusive presentation of its new systems; flexible, modular and easily reconfigurable, designed to provide an increasingly effective, quick response to the challenges of mass customization. SCM Division Director Luigi De Vito said “This was a chance to experience a new model of interaction between machines and industrial and collaborative robotics, ground-level logistic handling and software.”

The Open House summarised the goal of the new SCM product range: to supply the most user-friendly automation technology that considerably streamlines the factory layout, making it more efficient. It also creates a new model of interaction among humans, robots and machines, according to an open, safe cell design. The manufacturer also has the option to reconfigure the production process whenever this is necessary, to quickly process increasingly smaller “order to production” batches. The presentation showed a new, ‘smart and human’ factory, making progress in terms of work flow; minimising risky and repetitive human tasks where operators are able to focus on higher added value tasks.

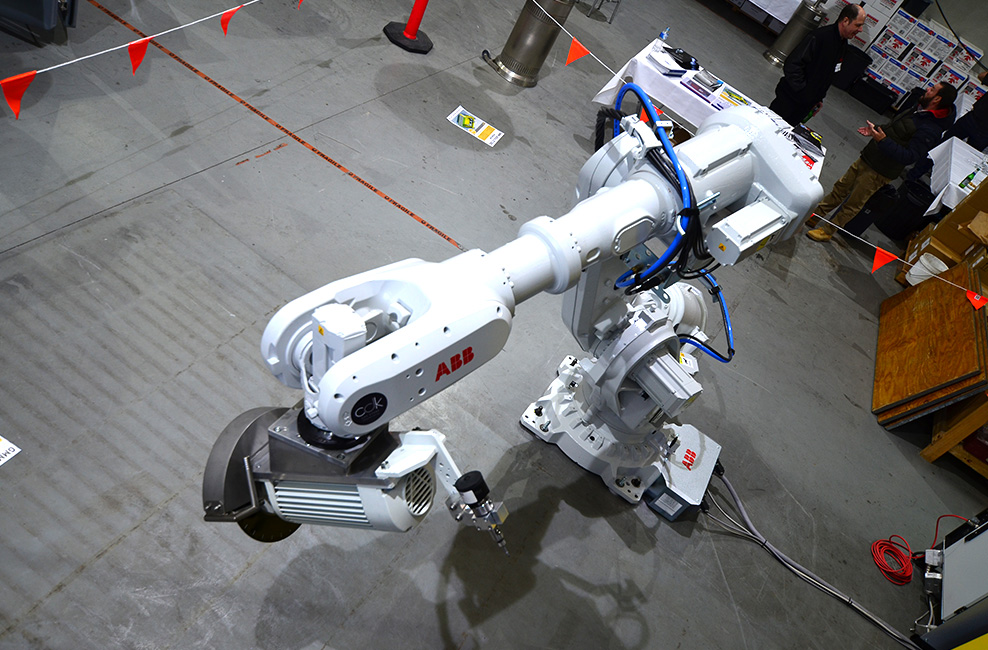

The presentation included flexible cells served by industrial anthropomorphic robots for repetitive and low added value tasks. It’s SCM’s ideal solution for sawblade cutting or sawing, milling, drilling and edge banding or for workpiece sequence rearranging between one process phase and the next. The unique presentation showcased SCM’s collaborative Islands in which workers and collaborative robots (cobots) work side by side, sharing the available work space safely, without the need for enclosures or similar systems. The cobots are used in the final process stages, such as assembly, hardware insertion, glue dispensing and surface finishing. Along the lines of Homag Group’s Autonomous Mobile Robots; SCM presented their system where flexible connections of machining cells and assembly islands is achieved through mobile robots that work in space while identifying the surrounding environment and selecting the most efficient route to their destination, safely avoiding obstacles, including humans. Master Watch Supervision software manages and monitors the state of each product and SCM’s Maestro connect have full control over the entire system.