A revolutionary new connector is currently undergoing trials in Italy. It’s a one-piece connector called Blu and is already being used in trials by one of Europe’s major furniture manufacturers and exporters.

Not yet available in Australia yet but one of those very interesting new developments that are worth keeping an eye on, the new Blu connector is a one-piece connector system for joining horizontal boards to vertical boards. It looks very suited to the kitchen, bathroom and cabinet industries but due to the very small hole it leaves after assembly; would be ideal for the office furniture sector.

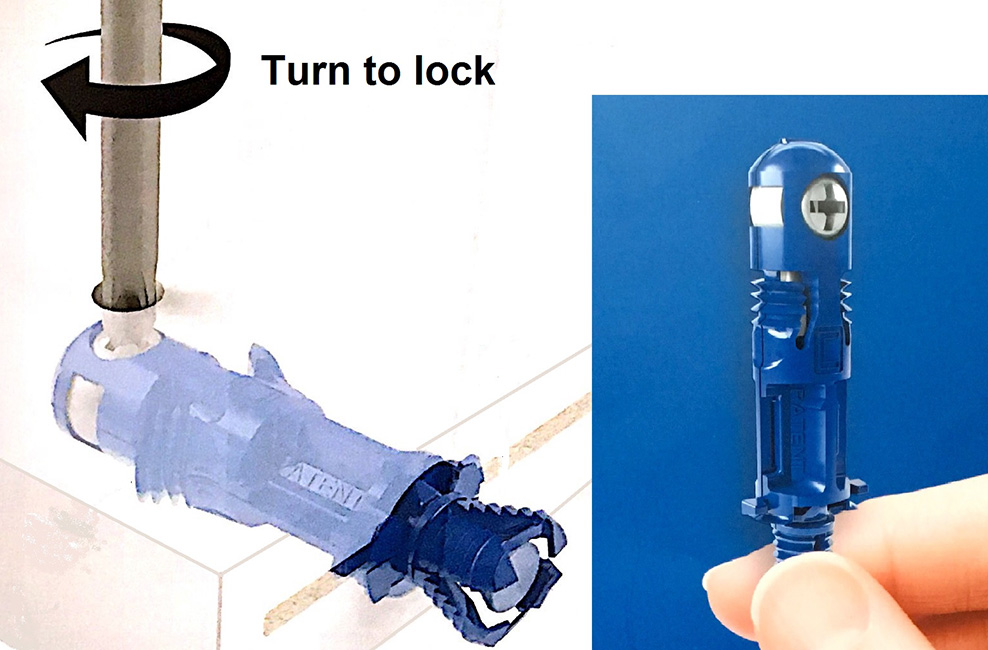

The connector is available in 8mm and 12mm sizes to suit boards from 12mm to 30mm in thickness. The fittings are designed to provide a simplified end user experience, reducing the assembly of industrial production furniture to a single element. The fitting makes it possible to assemble kit furniture without the need for additional hardware. It is a concealed connection system and apart from the small hole required to insert a screwdriver, is invisible. It offers a cleaner and more aesthetic look to the end product.

Ten million of these new connectors have been sold to one company alone to test the characteristics of the new connector. It’s also been tested by the Italian furniture testing laboratory CATAS; the connector is able to withstand the movement and stress of cabinet furniture, including stresses caused by transportation. We are advised that the product is not yet available for general distribution but the date is not far away.

How it works is that holes of either 8mm or 12mm diameter, depending on the connector size and the panel thickness are drilled into both members to be joined. You can see this in our image. A milled section (groove) is required to align the connector to a 6mm hole drilled into the horizontal member for the screwdriver tip. The fitting is inserted into the horizontal member and aligned with the small groove. The vertical member is then placed over the protruding expansion element of the connector. The screwdriver is turned clockwise until a click is heard, indicating that the expanding wings in the connector have opened and gripped the boards and pulled them together.

CAR (Components and Fittings) is the designer and maker of the product and claims that the new connector does away with a complicated set of machining and assembly processes but to the author, the same number of holes are required with an additional groove to align the connector. What makes this connector unique is that only one part (the connector) is required and only a small hole is visible after the connection is made.