The quality of your edge banding is affected by your equipment, raw materials, and operational proficiency. Let’s take a look at what the experts tell us.

Top Tips for your Edge Bander

EVA/PUR Hot Melt Edge banders are still the most used machines, they use a glue pot or cartridge to store and deliver the glue. For machines with a glue pot, an extra changeover pot will save a lot of time. Shut these machines off when not in use because the glue deteriorates over time. Clean the machine often. For the best adhesion to any product, acclimatise the board and edging to the factory environment over at least 24 hours for single sheets and three days for the boards in the middle of a pack. Some operators use a device to measure the temperature of both the board and edge to ensure they are the same.

In winter especially, the glue will set too quickly through the application of adhesive on cold surfaces, leading to a poor bond. It is advisable to process the board as soon as possible after cutting it on either a saw or CNC machine and using pre-milling cutters will provide the best edge for banding. Your edge bander should be kept clean and located in an area free of dust and away from draughts near doors, as temperature variations will play havoc on your edge banding results. It is recommended that indoor temperatures for edge banding are above 15C and the temperature of the board and edge is 18C and above.

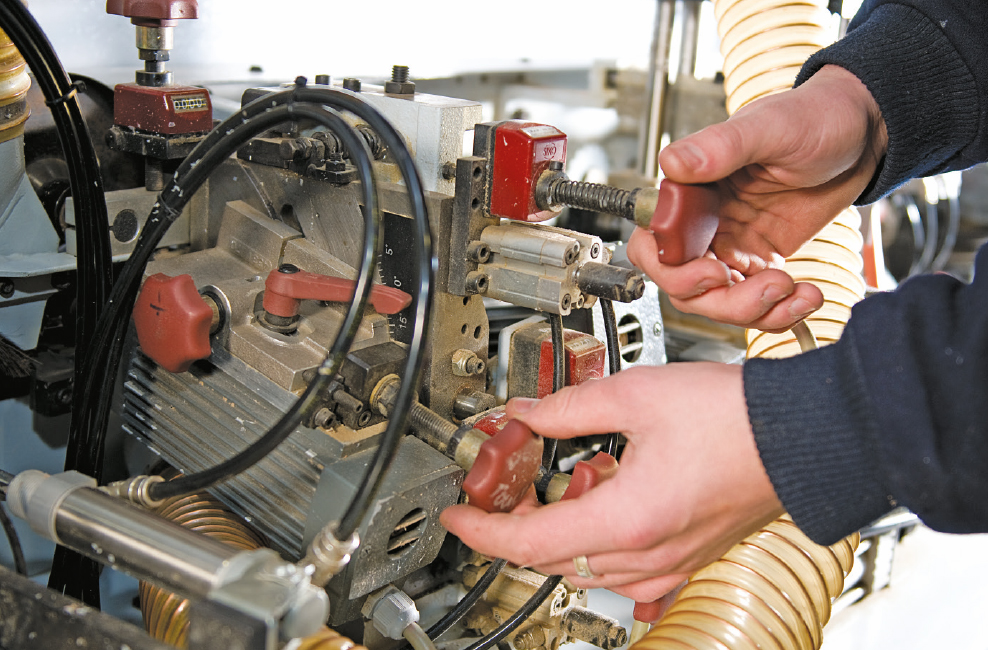

Your glue will be metered out by either a glue roller or nozzle. A nozzle system keeps the glue in the system until it is dispensed and is less likely to be contaminated. Roller systems continually recycle the adhesive through the glue pot and is likely to pick up dust from the factory. If you have a roller, set it 0.1mm to 0.2mm away from the board for a good spread of glue. This reduces fibre contamination on the roller, reduces contamination in the glue pot, reduces damage to the board edge and gives an even coating of glue.

Problems?

At the start of every shift, run a test piece and pull the edge off by hand to inspect the result. If the edge banding pulls off easily, hot melt adhesive remains on the chipboard and you can see the grid pattern of the glue application roller; the potential causes are as follows. Not enough adhesive has been applied, the room temperature is too low, the edge banding material is too cold, the hot melt adhesive temperature is too low, the feed rate is too low or there is too little pressure applied by application roller which should be set at 2.5 bar, depending on the machine.

If the edge banding pulls off easily, hot melt adhesive remains on the chipboard, but the hot melt adhesive surface is totally smooth (edge banding slips off) then the board and/or edge banding may be too cold. You should also check the hot melt adhesive type. If the hot melt adhesive largely remains on the edge band the temperature of the board material may be too high. If the join is not closed the problem may be eliminated by increasing the roller pressure, increasing the glue temperature, preheat the board or increase the feed speed.

Typical application temperatures in straight line edge banders vary widely based on the characteristics of the EVA being used but are normally in the range of 180 to 220 degrees Celsius. PUR is a reactive glue, and the glue pot should be set in the range of 120 to 150 degrees Celsius. You can preserve used PUR glue for up to 7 days. To achieve an invisible glue joint special care must be given to provide a clean edge for processing.

If you find indentations or scratches on the finished edge band you will need to clean the machine where the tape is drawn in, clean the pressure rollers. Blunt cutters and saws will damage the edge so keep these sharp. If you follow a board as it goes through the machine you may pick up where the damage is occurring. You might also find it’s better to have only one or two people work your machine; that person(s) will take more care and eventually become familiar with the machine and potential problems and remedies.

Storage

Edge banding tape should be stacked horizontally, and this will maintain the initial tightness of the roll. The best temperature is a constant room temperature of 17-20 degrees Celsius. Store edges away from dust and preferably in a windowless room to protect them from UV light that could destroy the applied primer. Veneer edgings and end grain veneer should be stored in a tightly sealed plastic bag. This prevents them from drying out and becoming brittle.

PVC releases toxic gas when burned so responsible disposal of unwanted edges is highly recommended. ABS edge tapes are far more popular than PVC in European workshops. The Swiss edge banding manufacturer Rehau says, “ABS is chlorine-free both during manufacturing and in the final product. Unlike PVC, ABS may be incinerated with general waste.”